Heat Exchanger Performance Testing

Graftel ISO/IEC 17025:2017-Accredited & Appendix B-Certified Heat Exchanger Testing Services

Graftel has over 20 years of support experience proving both equipment and on-site services to the nuclear power industry.

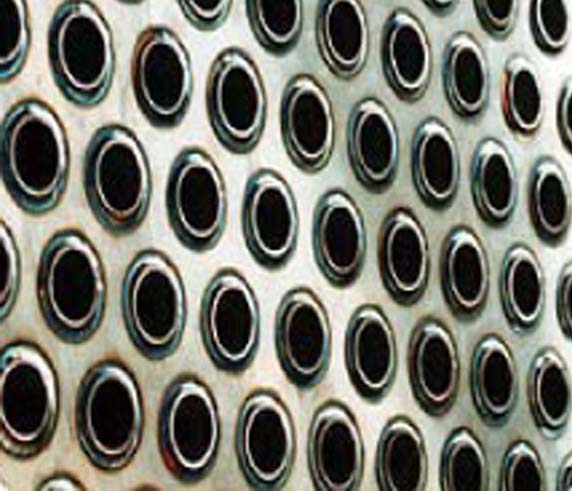

Heat exchanger performance testing, requires the onsite installation of instrumentation and data collection of information.

This information is processed using quality software to calculate parameters used to satisfy acceptance criterion which satisfy plant technical specification requirements.

Graftel’s approach to heat exchanger testing and analysis is consistent with the methodology presented in the EPRI document TR-107397, “Service Water Heat Exchanger Testing Guidelines.“

The testing services provided support the site’s heat exchanger testing program while keeping it consistent with EPRI guidelines utilizing the four step method outlined below.

- Test plan development. A testing plan is developed that includes the below items:

- Establish the test objectives, acceptance criterion, analytical methodology, test conditions and overall target test uncertainty

- Specification of measurement system and test methodology

- Test uncertainty analysis

- Test procedure development. The test procedure is developed in accordance with utility specific procedure requirements. The test procedure will provide the step-by-step process for ensuring the requirements of the test plan are carried out in a manner that will ensure the test is conclusive.

- The procedure will include instructions for proper installation of required sensors so that their performance stays within criteria specified by the test plan.

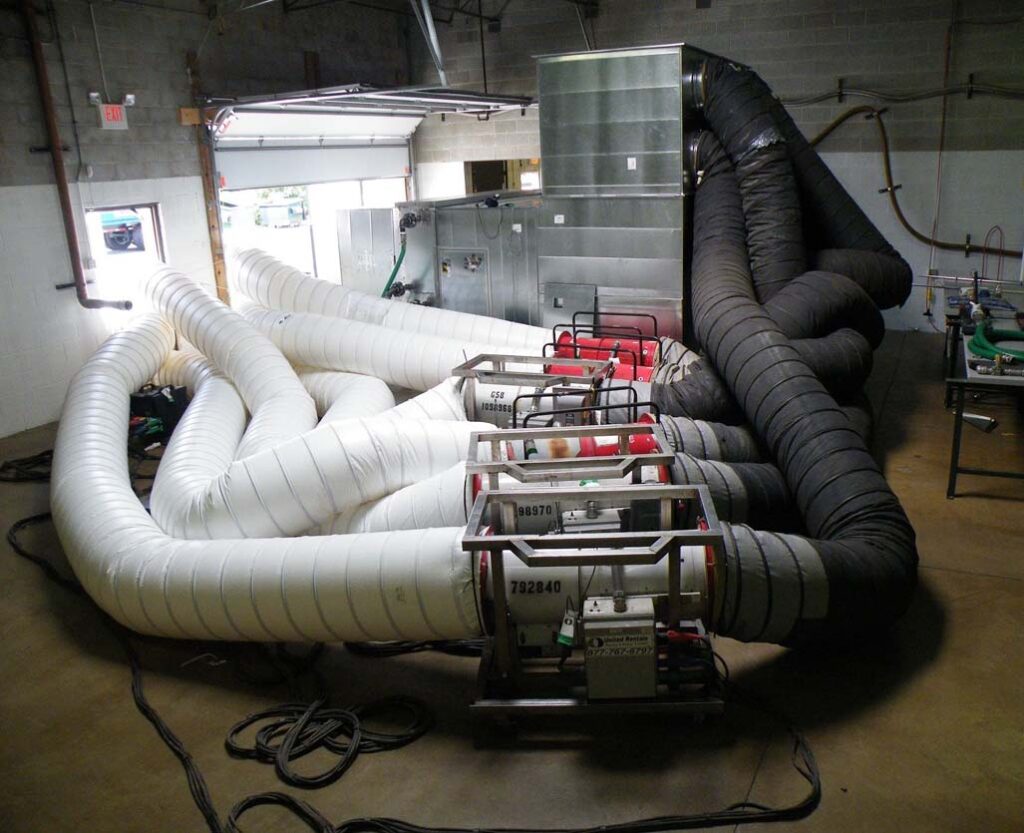

- Test implementation. This includes PCs loaded with data collection software, all required instrumentation and cabling, instrument calibration, on-site support installing instrumentation; obtaining and recording all test data as well as providing recommendations for operations personnel in establishing optimum system configurations and heat loads.

- Performance evaluation. This evaluation includes the following key elements:

- Statistical analysis of the test data reducing it to a set of input parameters for thermal performance analysis.

- Thermal performance analysis utilizing PROTO-HX™ or a utility-provided analytical package.

- A detailed post-test uncertainty analysis that provides the 95 percent confidence range around the calculated heat exchanger performance parameter.

- A final test report containing the above information.

Graftel, LLC. maintains an Appendix B QA program implementing 10 CFR 50 Part 21. Our calibration, software and engineering services have been recently audited and recorded in the NUPIC database.

In addition, Graftel’s is an ISO/IEC 17025:2017 accredited instrument calibration laboratory, certified by A2LA. Graftel’s team of recently nuclear plant badged personnel are instrumentation, calibration and data collection experts.

Engineering services for Numerical Advisory Solutions (NAS) are subcontracted by Graftel. They provide heat exchanger expertise as well as the analysis software, which is recognized as the industry standard. Their personnel have extensive experience in heat exchanger testing.